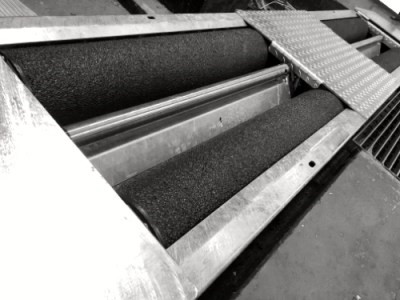

Occasionally informally called a brake tester machine, a roller brake tester is part of the inspection lane for an MOT test. Unlike a plate brake tester, it allows checking of the braking system on a static vehicle. The roller brake tester is installed at floor height and features motor-powered driving rollers, operating at a low speed.

The majority of MOT brake testers are of the roller type. By contrast, very few plate brake testers are approved for use by the DVSA.

By operating the rollers on the tester and applying the tested vehicles brakes, mechanics can include a load to force traducers within the roller bed. These forces are used to measure individual axle braking forces per wheel, and allow the measurement and assessment of any braking imbalance between the vehicle’s left and right side. The brake tester also includes an integrated weighing system which allows overall braking efficiencies to be automatically calculated by the software.

In the United Kingdom, ATL brake testers are classed as legislative products. This means that the Driver and Vehicle Standards Agency (DVSA) defines how the equipment operates. As such, its status as an ATL brake tester means all models of roller brake tester must work in the same way. In turn, this allows for reliable test results across the country, regardless of the workshop or specific roller brake tester used.